Background

The Home Depot was using two outdated and expensive warehouse management systems (WMS) that were difficult to customize. They decided to build their own WMS to be rolled out across all distribution centers, regardless of type.

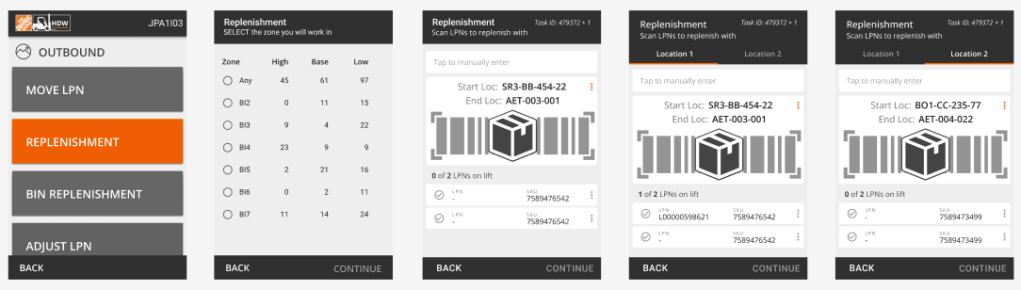

The Enterprise Supply Chain team was created with balanced Agile teams formed to design and develop each of the major workflows of a distribution center; inbound, receiving, putaway, replenishment, picking, and outbound. As UX Lead for the replenishment workflow, I drove end-to-end design—from research and concepting through prototyping and final delivery—in close partnership with product managers and developers.

Problem

After releasing the Replenishment module on the RF device for the warehouse floor workers, it became clear that too many replenishment tasks weren’t being completed in time to support outbound picking. Replenishment operations managers needed a way to monitor which tasks were completed and which remained.

Process

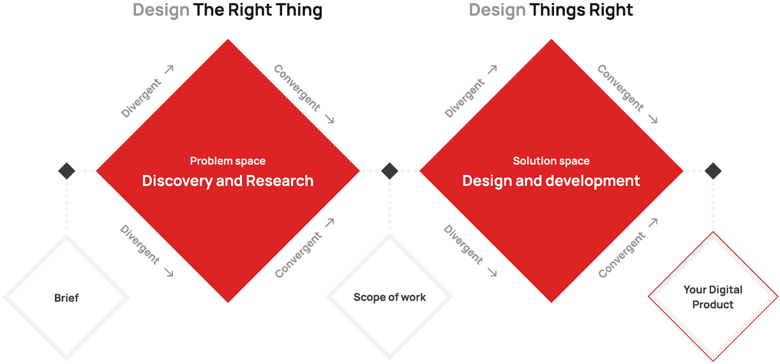

In order to make sure I was designing the right thing, I created a research plan to uncover what the operations managers needed to help them decrease the number of outbound picks that were missed because inventory wasn’t available when it was needed.

Research

I conducted six interview sessions with replenishment operations managers from different distribution centers—some in person, some virtual. After completing the interviews, I synthesized the information into key insights and turned them into actionable recommendations, which I presented to team members and stakeholders.

Solution

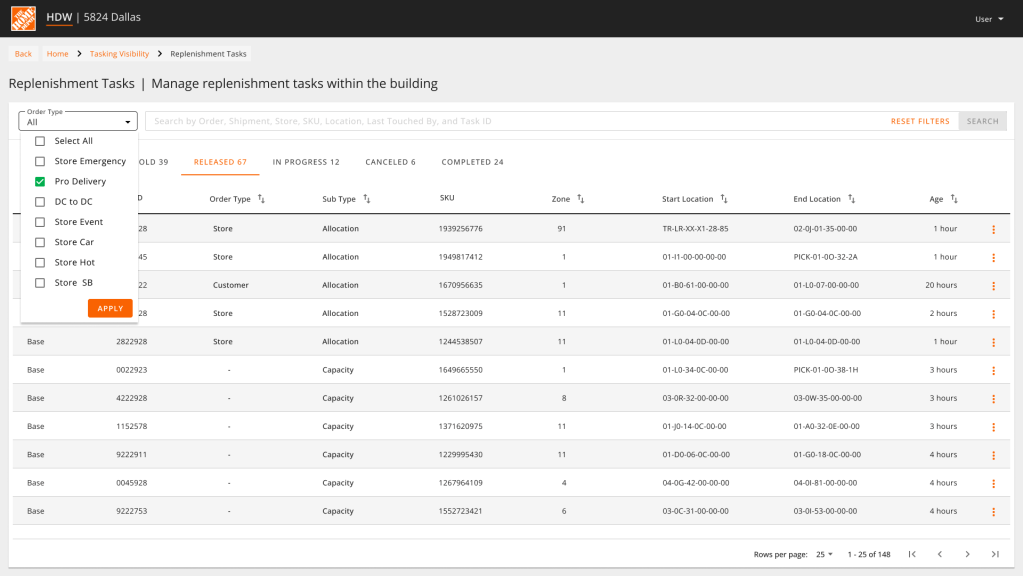

I designed a Replenishment Visibility Tool—a sortable table displaying all tasks for the current shift. They could be sorted by status; Released, In Progress, On Hold, Completed or Canceled. Within each status, tasks were further sorted by priority, with those requiring immediate attention appearing at the top of the list. Real-time updates kept the data current, and users could filter and search tasks using multiple criteria.

This dashboard lives on the operations manager’s desktop and became their go-to tool for monitoring floor progress throughout each shift.

Validation

Using the Supply Chain Figma design system, I created design comps and an interactive prototype to demonstrate real-time behavior. I then conducted user testing to gather feedback on data displayed, task prioritization and status comprehension, as well as search and filtering functionality.

Based on the findings, I refined the design comps and documented Jira stories for developer handoff.

Outcomes

By providing replenishment operations managers with real-time visibility into task status, priority, and inventory location, the tool enabled more effective staffing and dynamic task reprioritization. As a result, distribution centers improved order fulfillment performance—boosting fill rates by over 10%.