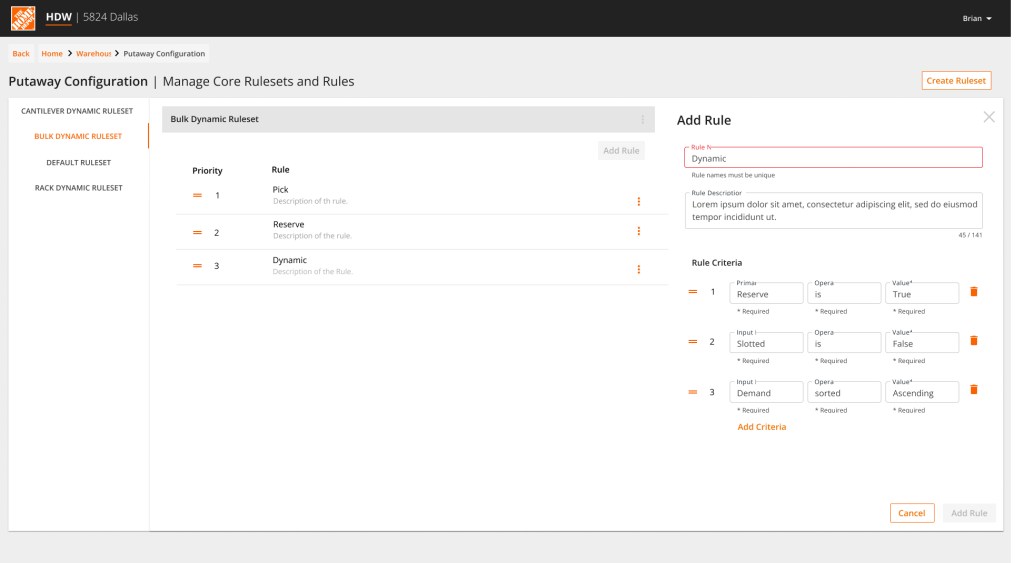

Problem

Inventory coming into the warehouse needs to be stored quickly and efficiently so it can be found and moved into picking areas to fulfill outbound orders.

Process

I couldn’t just enhance they current warehouse management systems that the Home Depot was using. They were outdated, DOS based systems that required extensive training to use. I needed to learn how they decided where the optimal place in the warehouse was to store new inventory. After discovering this, I would be able to create the process for setting up the rules so they could have confidence that the system would direct warehouse floor workers to move the new inventory into the desired storage location.

Research

I conducted multiple interviews with operations managers to understand how their current system creates rules for identifying where inbound inventory should be stored, any pain points they experienced, and how they wished the system might function in the future.

Solution

I created a Putaway Configuration module that allowed operations managers to create significantly fewer putaway rules than the previous system. The putaway rules relied on a warehouse configuration tool that I created that determined the relative travel distance from one storage location to another, one of the primary deciding factors in the decision making process.

Outcomes

The time to convert existing distribution centers to our new WMS or create rules for new SKUs coming into a distribution center was significantly reduced, as well as the travel time to move inventory to storage, staging or picking areas. This improved overall warehouse efficiency significantly.